Unlocking Apparel Manufacturing Efficiency: A Comprehensive Guide to Plant Layout

In the fiercely competitive apparel manufacturing industry, efficiency is paramount for success. A well-planned and optimized plant layout can significantly enhance productivity, reduce costs, and improve overall profitability. This comprehensive guide will delve into the key principles and best practices of plant layout in apparel manufacturing, providing you with the knowledge and tools to unlock the full potential of your facility.

5 out of 5

| Language | : | English |

| File size | : | 12738 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 79 pages |

| Lending | : | Enabled |

Understanding Plant Layout Fundamentals

Plant layout refers to the arrangement of machinery, equipment, and workstations within a manufacturing facility. The primary goal is to create a layout that minimizes material handling, optimizes production flow, and ensures a safe and ergonomic working environment.

Factors to Consider

When planning a plant layout, several factors need to be considered:

* Product mix: The variety and complexity of products manufactured. * Production volume: The quantity of products produced. * Equipment size and configuration: The dimensions, shape, and capabilities of the machinery. * Material flow: The path of materials through the production process. * Labor requirements: The number and skills of workers needed. * Safety and ergonomics: The well-being and efficiency of employees.

Types of Plant Layouts

There are various types of plant layouts commonly used in apparel manufacturing:

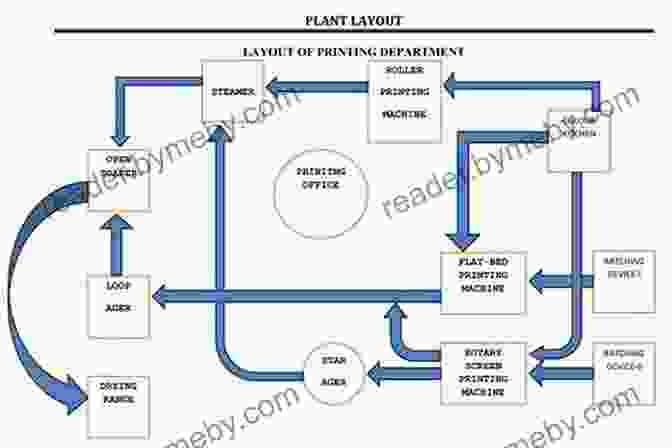

Process Layout

Arranges machinery and workstations based on similar functions or processes. Suitable for low-volume production with a wide product variety.

Product Layout

Arranges machinery and workstations in a sequence that follows the production flow of a specific product or family of products. Ideal for high-volume production with a limited product variety.

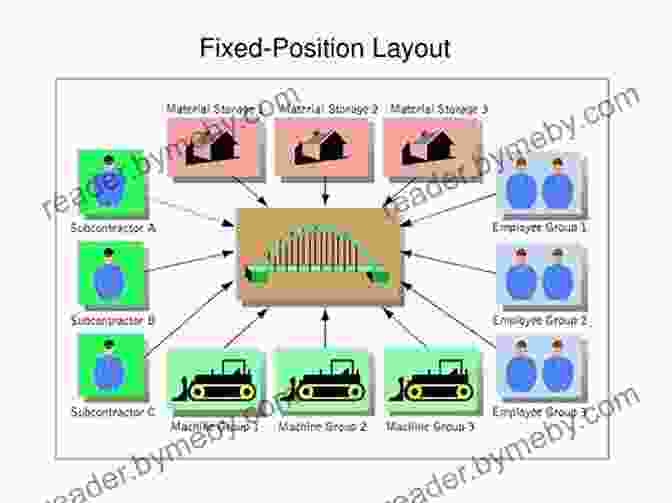

Fixed-Position Layout

The product remains stationary, and machinery and workstations are brought to it. Used for bulky or immobile products, such as ships or aircraft.

Cellular Layout

Combines process and product layout principles, creating production cells that are responsible for a specific part or stage of the manufacturing process. Enhances flexibility and teamwork.

Optimizing Plant Layout for Efficiency

To optimize plant layout for maximum efficiency, consider the following best practices:

Minimize Material Handling

Design the layout to minimize the distance and frequency of material movement between workstations. Use conveyors, automated guided vehicles (AGVs),or overhead cranes to reduce manual handling and improve productivity.

Establish Smooth Production Flow

Ensure that the flow of materials and products through the facility is smooth and uninterrupted. Avoid bottlenecks and backtracking by carefully sequencing processes and balancing workloads.

Maximize Equipment Utilization

Place equipment strategically to optimize production capacity and minimize downtime. Consider factors such as maintenance requirements, access to materials, and operator visibility.

Create a Safe and Ergonomic Environment

Design the layout to ensure a safe and comfortable working environment for employees. Provide adequate lighting, ventilation, and access to emergency equipment. Implement ergonomic principles to reduce fatigue and prevent injuries.

Promote Communication and Collaboration

Create a layout that fosters communication and collaboration among team members. Place workstations in close proximity to facilitate teamwork and information sharing. Establish clear lines of sight and communication channels.

Case Study: Plant Layout Optimization in a Garment Factory

A garment factory implemented a comprehensive plant layout optimization project that resulted in significant improvements in efficiency and productivity.

* Material handling reduced by 30%: Automated guided vehicles (AGVs) were introduced to transport garments between workstations, reducing manual handling and freeing up operators for more value-added tasks. * Production flow improved by 25%: The layout was redesigned to optimize the flow of materials and garments through the facility. This reduced bottlenecks and backtracking, resulting in faster production times. * Equipment utilization increased by 15%: Machinery was strategically placed to minimize idle time and maximize production capacity. This led to a significant increase in output without additional capital investment. * Improved ergonomics and safety: The layout was modified to create a more ergonomic and safe working environment. This resulted in reduced fatigue, fewer injuries, and improved employee morale.

Plant layout plays a critical role in the efficiency and profitability of apparel manufacturing facilities. By understanding the fundamentals of plant layout, considering the various types of layouts, and implementing best practices for optimization, manufacturers can unlock the full potential of their operations. This comprehensive guide provides the knowledge and tools necessary to create a well-planned and optimized plant layout that maximizes productivity, reduces costs, and enhances overall performance in the competitive apparel manufacturing industry.

5 out of 5

| Language | : | English |

| File size | : | 12738 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 79 pages |

| Lending | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Laura Sebastian

Laura Sebastian Marc Cashman

Marc Cashman V F Gutierrez

V F Gutierrez Nina Riggs

Nina Riggs Lukas Thao

Lukas Thao Kirsty Hartley

Kirsty Hartley Phil Chan

Phil Chan Hitomi Shida

Hitomi Shida Lionel Groulx

Lionel Groulx Matthew Sturm

Matthew Sturm Megan Kate Nelson

Megan Kate Nelson Ryan Beck

Ryan Beck Sonia Misra

Sonia Misra Mindy Hardwick

Mindy Hardwick Steven K Scott

Steven K Scott Rosanna Casper

Rosanna Casper Nitish Singh

Nitish Singh Ted Starkey

Ted Starkey Neal Stephenson

Neal Stephenson William Powell

William Powell

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Curtis StewartUnveiling the Masterful Strokes: 519 Color Paintings of Ivan Shishkin, the...

Curtis StewartUnveiling the Masterful Strokes: 519 Color Paintings of Ivan Shishkin, the...

Harrison BlairUnlocking Confidence with English Ks1 Age: A Comprehensive Guide for Young...

Harrison BlairUnlocking Confidence with English Ks1 Age: A Comprehensive Guide for Young... Jay SimmonsFollow ·12.6k

Jay SimmonsFollow ·12.6k Andy HayesFollow ·12.5k

Andy HayesFollow ·12.5k Dion ReedFollow ·11.5k

Dion ReedFollow ·11.5k Rodney ParkerFollow ·13.2k

Rodney ParkerFollow ·13.2k Dallas TurnerFollow ·18.7k

Dallas TurnerFollow ·18.7k Greg CoxFollow ·2.5k

Greg CoxFollow ·2.5k Arthur MasonFollow ·8.8k

Arthur MasonFollow ·8.8k Alexandre DumasFollow ·19.7k

Alexandre DumasFollow ·19.7k

Wayne Carter

Wayne CarterThe Beginner's Guide to Making an Old Motor Run Forever

If you're like most...

Deacon Bell

Deacon BellNepali Adventure: Kings and Elephant Drivers,...

In the heart of the...

Carlos Drummond

Carlos DrummondThe Romantic Revolution: A Journey Through History and...

Unveiling the...

Kazuo Ishiguro

Kazuo IshiguroUnlock Your Inner Innovator: Dive into the New Wave...

Embark on a Transformative Journey of...

William Golding

William GoldingCrazy Horse: The Lakota Warrior's Life and Legacy

In the annals of Native...

Hector Blair

Hector BlairMildred and Richard Loving: The Inspiring Story of...

Mildred and Richard Loving were an...

5 out of 5

| Language | : | English |

| File size | : | 12738 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 79 pages |

| Lending | : | Enabled |